Er hvid eg råd resistent? I de fleste anvendelser i den virkelige verden, hvid eg anses for at være rådbestandig -især kernetræet. Denne ...

Læs mere Designparketgulve henviser til design af trægulve, der er konstrueret af små planker og placeret til at danne geometriske mønstre. Efter at have toppet i popularitet i 1960'erne, er dette detaljerede gulvdesign for nylig kommet tilbage i rampelyset.

Designparketgulve er en type trægulve lavet ved at arrangere små lameller af træ i forskellige, gentagne mønstre. Traditionelle parketgulve blev installeret et stykke ad gangen. I mellemtiden er moderne parketgulve i fliseform, med trællaser bundet til et bagmateriale.

Strenge kvalitetskontrolprocesser er på plads i hele fremstillingssystemet for at sikre, at konsekvent kvalitet produceres.

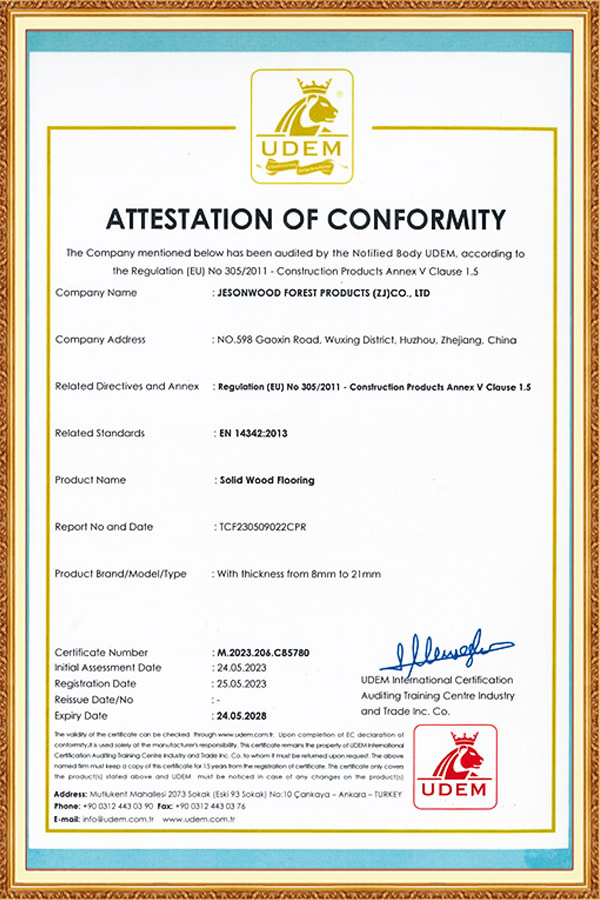

CE Solid Wood Certificate

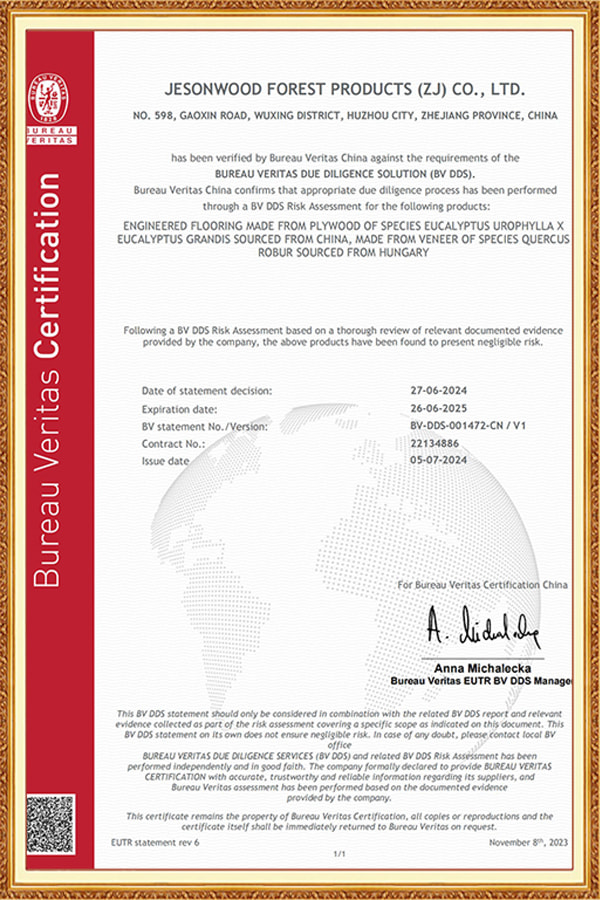

Endelig DDS_Jesonwood Forest Products (ZJ) co., Ltd.

PEFC SGS

Er hvid eg råd resistent? I de fleste anvendelser i den virkelige verden, hvid eg anses for at være rådbestandig -især kernetræet. Denne ...

Læs mereHvor meget koster det at lave trægulve i 2026? Når folk spørger "hvor meget koster det at lave trægulve", vil de normalt have et praktisk tal, de ka...

Læs mereHickory træ hårdhed: hvad det egentlig betyder under fødderne Når folk taler om hårdhed i hickorytræ, refererer de normalt til Janka-hårdhedstesten ...

Læs mereNår et flydende trægulv over beton er det rigtige valg A flydende trægulv over beton er typisk bygget af konstrueret hårdttræ (klik-lås e...

Læs mereKey Differences Between Traditional and Engineered Design Parquet Flooring Explained Clearly

When it comes to choosing between traditional and engineered design parquet flooring, the decision goes far beyond just aesthetics. While both options present the signature geometric patterns that define parquet—such as herringbone, chevron, or basket weave—their construction and performance characteristics differ in meaningful ways. Understanding these differences can help buyers make informed decisions that align with their project’s demands, whether it's a luxury home, a boutique hotel, or a high-traffic commercial setting.

Traditional design parquet flooring is typically crafted from solid hardwood, with each small slat individually laid on-site to form intricate patterns. This method offers unmatched authenticity and can be sanded and refinished many times over the years. However, solid wood is highly sensitive to moisture and temperature fluctuations, making it less ideal for areas with variable climates or underfloor heating. Installation also tends to be more labor-intensive and time-consuming, which may increase upfront costs—something to consider for time-sensitive commercial installations.

Engineered parquet, by contrast, uses a layered construction: a top veneer of real hardwood adhered to a stable core, often made of plywood or HDF. This modern approach significantly improves dimensional stability, reducing the risk of warping or gapping over time. It also allows for easier and quicker installation, especially since many engineered design parquet flooring products come in pre-assembled tiles with the pattern already set. This feature makes it possible to retain the luxurious visual appeal of traditional parquet while simplifying the logistics, especially for large-scale rollouts.

Another key factor is thickness and refinishing potential. While traditional parquet typically allows for multiple sandings, high-quality engineered parquet can also be refinished, depending on the thickness of the top wood layer. For most practical purposes, especially in commercial spaces where wear is concentrated in specific areas, engineered floors can perform just as reliably with proper care and strategic refinishing. It’s a balance of convenience and longevity that appeals to both designers and procurement professionals.

From a cost perspective, engineered design parquet often provides better value when considering installation efficiency, adaptability, and maintenance over time. While traditional options may carry a premium due to craftsmanship and material volume, engineered alternatives are increasingly competitive—especially when sourced from reputable manufacturers with strong quality control. As a manufacturer experienced in both formats, we help clients weigh these factors against their specific needs to recommend flooring solutions that meet their aesthetic and functional goals.

Ultimately, both traditional and engineered parquet have a place in today’s flooring market, and choosing between them depends on the environment, project timeline, and design vision. Whether you’re curating a timeless interior or delivering a fast-paced renovation, understanding the structural nuances behind design parquet flooring is key to long-term satisfaction. With proper guidance and quality assurance, either option can become a stunning and lasting feature of any space.